In the field of high-precision machining, the hydraulic collet in the hydraulic toolholder is extremely critical, and its performance is directly related to the machining accuracy, efficiency and cost. In this article, let's take a look at the new BRIGHT-TOOLS hydraulic collet.

Hydraulic Collet Working Principle

By applying pressure through the hydraulic system, the inner wall of the collet produces uniform radial contraction or expansion, so as to tightly hold or loosen the tool to achieve reliable clamping and positioning.

Problems Generally Encountered with Hydraulic Collet

Insufficient clamping force leading to tool drop: Hydraulic collets sometimes have insufficient clamping force, resulting in tool loosening and falling off during the machining process, which not only seriously affects the machining process, but also may lead to tool damage, workpiece scrap and other problems.

Unstable precision and large deviation: the accuracy of some of the hydraulic collet performance is poor, there will be precision fluctuations in use, it is difficult to ensure the consistency of machining, resulting in substandard machining accuracy of the workpiece, unable to meet the demand for high-precision machining.

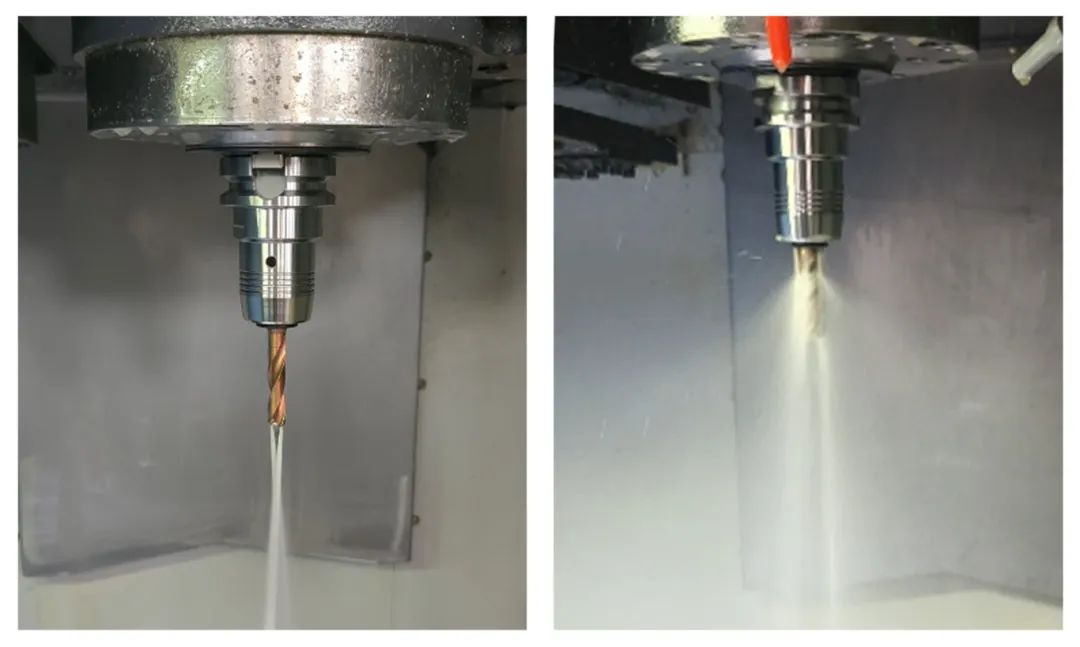

Poor water-stopping ability: some hydraulic cartridges are unable to achieve water outlet from the centre or have low pressure-bearing capacity, resulting in poor coolant supply, poor tool heat dissipation, accelerated wear, and often interrupted machining, which not only increases tool loss but also reduces work efficiency.

BRIGHT-TOOLS hydraulic collet new upgrade

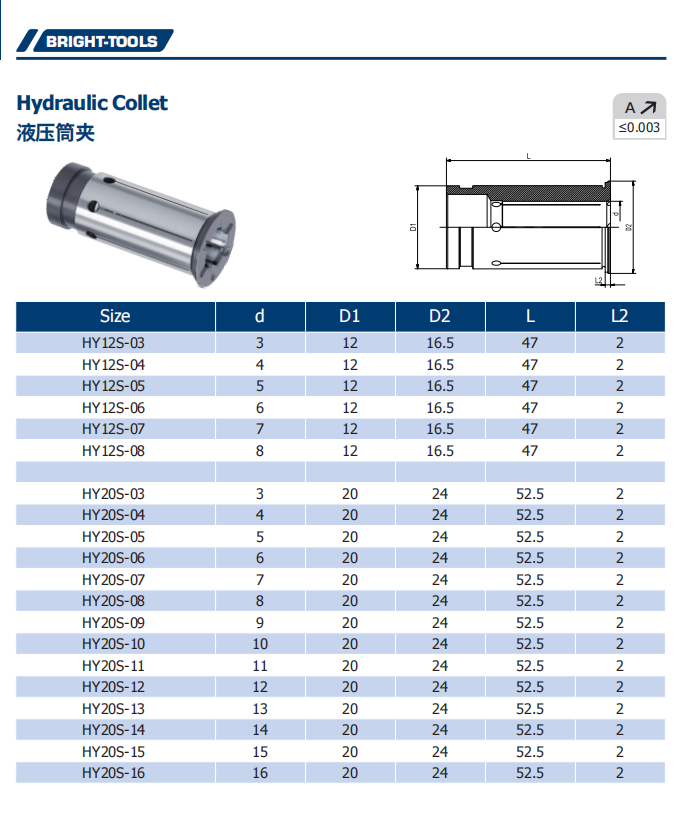

1) High precision:slit grooving technology, when the outer circle of the collet is subjected to external force, its inner hole can achieve extremely uniform deformation, which ensures the ultra-stable state of precision, and the radial runout precision can be accurately controlled within 3μm.

(2) High clamping force: the design of plum blossom end face, this unique structure makes the collet not only can be clamped by the side wall, but also the end face can be contracted inward, so that the collet can form a greater clamping force;

(3) With the characteristics of the centre of the water outlet: it can withstand the coolant pressure of 80bar; in order to achieve a better effect of the centre of the water outlet, a sealing ring has been added to the port of the collet;

GOLDEN JIE HYDRAULIC CYCLISTERS

1) Hydraulic collets - centre of water outlet ) Hydraulic Collet - Centre Water Out:

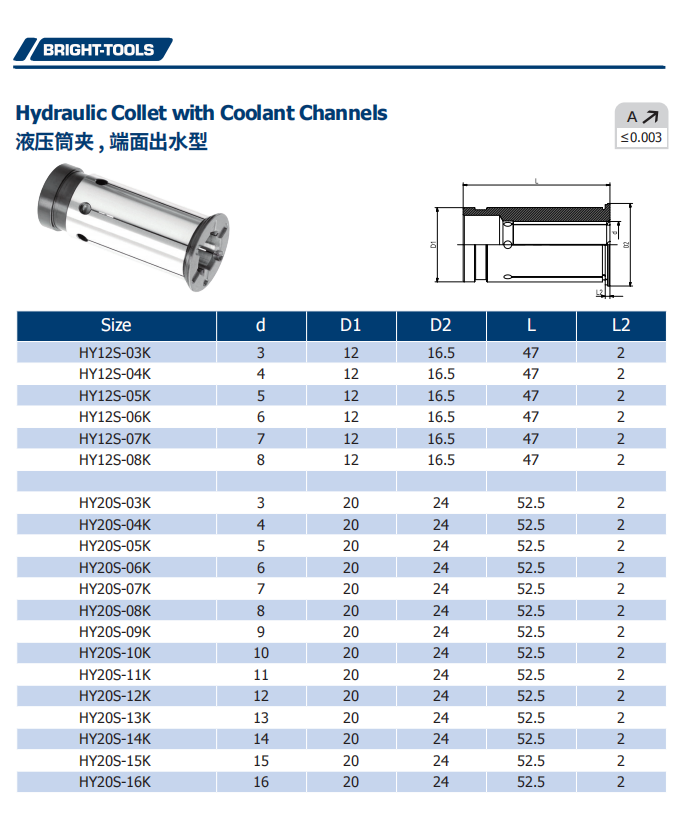

2) Hydraulic Collet - Face Water Out:

Ginger CNC has not only the centre water out standard collet, but also the face water out collet. When encountered with non-centre through-hole tools, it can discharge water from the end face, straight to the machining part, cooling down quickly to ensure the smooth progress of machining.

BRIGHT-TOOLS CNC hydraulic collets, combining stable quality and affordable price, are your best choice for efficient precision machining.

Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include GROB, TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

According this equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

The Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.

www.bright-tools.com